LASER SOURCES

Wavelength

193 | 248 [nm]

Pulse Energy (1)

400 | 700 [mJ]

Max. Rep. Rate

50 | 50 [Hz]

Average Power

15 | 30 [W]

Pulse Duration

25 | 25 [ns]

Beam Dimensions (3) – (V x H) – 24 x 6 to 12 [mm^2]

Repetition rate

10 [Hz]

Energy/pulse

1064 [nm] 850[mJ]

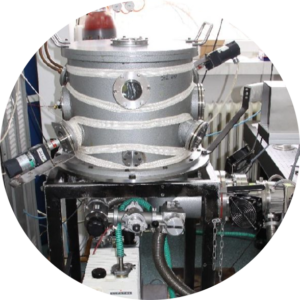

DEPOSITION CHAMBERS AND ACCESORIES

Stainless steel high vacuum chamber, with Cu gaskets or viton O-rings with vacuum performances of up to 10^-6 torr

– 42 cm diameter

– 4 CF 150 flanges (for heater, target, substrate and vacuum pump)

– temperature controller, model Eurotherm 2146, tmax = 1200°C

– high vacuum pumping system (vacuum system with turbomolecular high – – capacity pump,Varian TV 301) Pmin= 10^-6 Torr

– 2 gauges measuring the pressure inside the chamber

– gas flowing controller MKS50

– carrousel type system with 5 target holders

Stainless steel high vacuum chamber, with Cu gaskets or viton O-rings with vacuum performances of up to 10^-8 torr

– 45.72 cm diameter

– 4 CF 150 flanges (for heater, target, substrate and vacuum pump)

– 2 CF 50 ports for laser beam acces in the chamber

– 4 CF 35 flanges for gauges and lateral view

– 3 CF16 flanges for gas valve, evacuation valve, and Pirani probe

– Stanford residual gas analyzer RGA200 200 amu RGA w/RS-232 interface (detector: Faraday cup, electron multiplier, resolution better than 0.5 amu@10% – peak height, operating range10^-4 Torr)

– gas flowing controller MKS

– high vacuum pumping system Pffeifer

– carrousel type system with 5 target holders

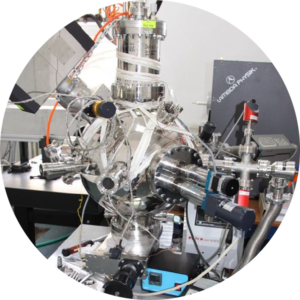

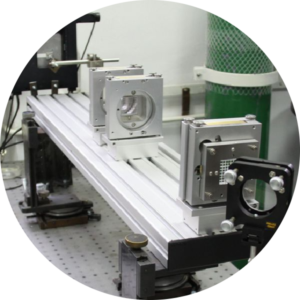

Orientation of the laser beam – horizontally

Type of homogenizer – single axis

Elements long axis – 8 widths: 4mm, lengths: 40 mm

Elements small axis – 8 widths: 4mm, lengths: 40 mm

Condensor lens diameter – 50 mm

Type of mount – L-mount, compact

Coating – L-mount, compact

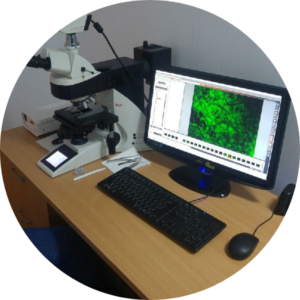

CHARACTERIZATION

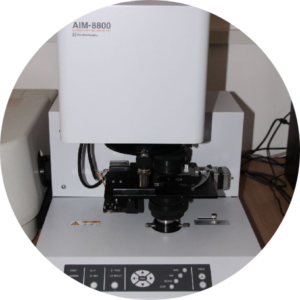

Objective in Normal Plan :

– 5X/0.12- free working distance : 14 [mm],

– 10X/0.25 – free working distance : 17.6 [mm], 20X/0.4 – free working distance : 1.15[mm],

– 40X/0.75 – free working distance : 0.37 [mm]

– 100X/0.85 – free working distance : 0.33[mm],

-Florescent filter

-Contrast Method : Transmitted Light (Bright field, Dark field incident/transmitted light, Phase contrast, Polarization, incident/transmitted light)

– Incident Light : Florescent

– LCD-Display for presenting all relevant microscope parameters

– Hg 100W lamp

– Digital camera LEICA – 5Mpixels, resolution 2560×1920, fast live image 1280×960 pixel with 18fps

Baseline Flatness ±0.0010A, 200-800nm, 1.0nm SBW, smoothing

Data Interval 10, 5, 2, 1.0, 0.5, 0.2, 0.1nm

Detector Type Dual Silicon Photodiodes

Dimensions (L x W x H) 62.2 x 48.6 x 27.9cm

Drift <0.0005A/hr, 500nm, 1.0nm SBW, 1 hr warm-up

Lamp Xenon Flash Lamp, 3

Photometric Accuracy

Instrument 1A: ±0.006A

2A: ±0.010A

Photometric Display -0.3 to 4.0A

Photometric Range >3.5A

Photometric Repeatability ±0.0002A

Scan Ordinate Modes Absorbance, % Transmittance, % Reflectance, Kubelka-Munk, log (1/R), log (Abs), Abs*Factor, Intensity

Scan Speed <1-6000nm/min, variable

Spectral Bandwidth Variable: 1.0nm; 2.0nm; AFBG Microcell optimized; AFBG Fiber optic optimized; AFBG Materials optimized

Wavelength Accuracy ±0.5nm (541.9, 546.1nm mercury lines), ±0.8nm (full range 190 to 1100nm)

Wavelength Range 190 to 1100nm

Wavelength Repeatability ≤0.05nm (546.11nm mercury line, SD of 10 measurements)

Weight (Metric) 14.4kg

Sample size : 25,4 x 25,5 x 1905 [mm] (1″ x 1″ x 3/4″)

Standard Scanning mode : Vibrating (Tapping), Non Vibrating (Contact), Phase, LFM

Scanner ; 15 x 15 x 7 μm

Video Optical Microscope : Zoom to 400X, 2 μm resolution

Stage and Ebox Size : Compact Tabletop Design

15 Micron XYZ Scanner

» Type Modified tripod

» XY Linearity < 1%

» XY Range > 15 μm

» XY resolution < 1 nm closed loop

< 0.3 nm open loop

» XY Actuator type Piezo

» Sensor type Strain Gauge

» Z Range > 7 μm

» Z Linearity < 5 %

» Z feedback noise < 0.08 nm*

» Z Actuator Type Piezo

» Z Sensor type None

Sample Holder

» Type Magnet

» Max Lateral Dimensions 1”

» Max. Height 0.75”

Light Lever AFM Force Sensor

Laser Type 670 nm diode, < 1 mw

Focal length 550 mm

Aperture f/6.4

Spectral range 150 to 1500 nm w/120g/mm grating, 150 nm to 40 microns w/appropriate gratings

Grating size 76mm X 76mm

Number of gratings on turret up to 3

Flat field size 30 mm X12 mm

Resolution with Exit Slit and PMT 0.025 nm

Wavelength Accurancy 20 nm

Repeatability 0.075 nm

Spectral Disperssion @500 nm 1.34 nm/mm

Magnification 1.1

Stray light 1×10^-5

Scan speed 160 nm/s

Step size 0.002 nm

Computer interface High speed USB

Optical axisi (height from bottom of instrument) 98 mm

i-Spectrum ICCD detector

Intensifier type 18 UVF

Input window UV grade quartz

intensifier type Gen II

Photocathode S20

output window Fiber optic

Coupling between intensifier and CCD By t

Interferometer – Michelson interferometer (30° incident angle)

/ Dynamic alignment system

/ Sealed and desiccated interferometer

Optical system – Single beam optics

Beam splitter – Germanium-coated KBr plate

Beam source – Ceramic

Detector – High sensitivity pyroelectric detector (DLATGS)

Wavenumber range – 7800 cm^-1-350 cm^-1

Resolution – 0.85 cm^-1, 1 cm^-1, 2 cm^-1, 4 cm^-1, 8 cm^-1 or 16 cm^-1

Calculation wavenumber interval – 0.25 cm^-1, 0.5 cm^-1, 1 cm^-1,2 cm^-1 or 4 cm^-1

Wavenumber accuracy – ±0.25 cm^-1

S/N ratio – 20000:1(Peak-to peak,resolution 4 cm^-1, approx.2100 cm^-1,1minute scanning)

Mirror speed 3-step selection from 2.8 mm/sec, 5mm/sec,or 9 mm/se / A scanning at 4 cm-1 takes from 2-3 sec

Data sampling He-Ne laser

Gain control – Automatic or manual from x1-x128 in 2 steps

Sample compartment – 200(W)x230(L)x170(H) mm

MCT detector wavenumber range 5000 – 720 cm-1 (narrow band)

5000 – 650 cm-1 (middle band)

Aperture resolution 1 micron (X and Y axes), 1 degree (theta axis)

X-Y stage resolution 1 micron

Mountable sample thickness max 40 mm (reflectance analysis)

max 10 mm (transmittance)

Maximum load on stage 0.6 kg

Signal/noise ratio

Measuring mode: transmittance

Aperture size: 50×50 microns

Resolution: 8 cm^-1

Accumulation times: 60 times.

OTHER LABORATORY EQUIPMENT

Model CWF (volume) 13 liters

Max Temp (°C) 1100

Max Power (watts) 3100

Holding Power (watts) 1300

Nominal Heat Up Time (mins) 55

Temperature Sensor Type K thermocouple

Maximum Temperature : 1200 °C

Max continuous operating temp 1100(°C)

Ceramic Tube Inner Diameter : 25[mm]

Ceramics Insulation Plugs

Lenght of uniform temperature : +/- 5 °C – 90 [mm]

Max power (W) 700

Holding power (W) 200

Thermocouple type N

Digital Controller 3216P5

Programming temperature controller with 8 segment pairs, each a ramp and a dwell.

Posibility of programing 5 programs

Temperature range (± °C), 50°C above ambient to 300

Temperature variation (± °C) at 700°C – 0.8

at 1500°C – 2

at 3000°C – 3.7

Temperature fluctuation (± °C) – 0.3

Heating up time (min) to700°C – 7

to 1500°C – 22

to 2500°C – 45

Type Near-infrared lamp high temperature type high vacuum type

Temperature range Room temperature to 1200 °C

Max heating rate 50 C/s in vacuum

45 C/s in nitrogen

Temperature uniformity 4°C at 1200C in vacuum

9°C at 1200 C in nitrogen

Heating atmosphere In air, vacuum or inert gas

Sample size 20W x 20L x 2T (mm)

Lamp rating 1kW

Chamber volume: 1.9 L

Voltage supply 230 VAC

Gas connections 1

Vacuum pump speed min. 1.5 m3/hr

Generator LF (100 W)

RF manual (100 W)

RF automatic (100 W)

MW (260 W)

Electrode RIE / PE

Further options Corrosive gas

Rotary drum

Monomer bottle

Heating plate

Pressure gauge

Pressure reducer

Gas bottle

Faraday box

Multi-level electrode

Mass flow controlle

Rotor type : RA-5008

Capacity : 50×8

Max speed(rpm) : 6500

Max RCF (relative centrifugal force)(×g) : 5010

Max tuve size (mm) : 29.5×117

LED digital display

Speed of grinding jars (min^-1)

400 – with grinding jar type “S” standard 500 ml special steel and 7 grinding balls, 30 mm diameter in tungsten carbide

500 – with grinding jar type “S” standard 250 ml tungsten carbide and 5 grinding balls 30 mm diameter in tungsten carbide

580 max – with grinding jar type “S” standard 50 ml tungsten carbide and 3 grinding balls 20 mm diameter in tungsten carbide

Rated power (W) approx. 100

IP rating IP40/IP20 vessel to casing

Rated speed of motor (cm^-1) 2500

Type : SONIC-250W

Frequency : 20-25kHz

Frequency automatic tracing ultrasonic time set : 0.1-9[s]

Working-off Time set : 0.1-9[s]

Overall Time set : 0.1m-99 [min]

Ultrasonic Power : 20-250 [W]

Adjustable random amplitude transformer : Φ6

Optional amplitude transformer : Φ3

Crusher capacity : 0.2-200 [ml]

Duty Cycle : 0.1-99.9%

Power : 220±5%

Work Environment : Indoor (no damp, sunshine and corrosive gas)

Aplicable Range of amplitude transformer (probe) with various specifications

Amplitude transformer (probe) ΦmmΦ3Φ6Φ10

Crusher Capacity ml0.2-10,10-100,100-250

Max load 0,8/3 g

Readability 1/10 µg

Repeatability* 1 µg

Linearity ±3 µg

Eccentric load deviation 3 µg

Sensitivity offset 1,5 × 10-6 × Rt

Sensitivity temperature drift 1 × 10-6 / °C × Rt

Minimum weight (USP) 3 mg

Minimum weight (U = 1%, k = 2) 0,2 mg

Pan size ø 30 mm

Weighing chamber dimensions 90 × 90 mm

Stabilization time 5s

Calibration automatic (internal)

Working temperature +18 ° – +30 °C

Interface 2×USB, RS 232, Ethernet, 2in/2out (digital)

Display 5,7’’ touch screen

* Repeatability is expressed as a standard deviation from 10 weighing cycles.

High purity water system TKA Pacific UP/UPW6 – making high purity water for use as such or further purification to ultra pure water.

Typical applications are:

– Rinsing of glassware

– Preparing or diluting buffers, reagents, tissue culture media, and stains

– Preparing samples for relatively undemanding analytical methods such as flame AAS

Performance

– Flow rate (at 15 oC): 6 L/h

– Retention of bacteria and particles: 99%

TKA GenPure Ultra Pure Water System accessory with UV-intensity and TOC monitoring – reducing very low organic/inorganic contaminant concentrations in high-purity feedwater even further by UV photo-oxidation at 185 and 254 nm irradiation wavelengths

Ultra pure water quality:

– Conductivity: 0.055 µS/cm

– Bacterial content: 1 CFU/ml

– TOC 1: 10 ppb

Maximum capacity (mc/h) 950

Noise (db) >62

Piping vent (mm) 200

EQUIPMENT electric control panel

2 meshes 220V – 16A

table: fireproof laminated plastic, ceramic plates, stainless steel AISI 304 – 316, polypropylene, granite stone

centrifugal exhauster VSB 20

– Class II protection cabinet EN-12469

– vertical laminar flow-

– stainless steel AISI 304 walls and workspace

Model BSC-EN 1-3

Int. dims (Lxhxl) (mm) 885 x 660 x 580

Ext.dims (Lxhxl) (mm) 1090 x 1470 x 780

Power (kW) 0,7

Opening (mm) 200

Temperature variation (°C) <4

Electrical supply (Hz) 220 V/50

Noise (dBA) < 59

Lighting (lux) > 1.000

Vibrations <0,005 mm rms

ACCESSORIES

UV Lamp